1.Chamfering Machine

Pipe diameter: 2’’ – 6’’

Pipe length: 5m - 12.8m

This machine performs chamfering on the pipes that come from the tube mill. The installation is inline the tube mill and to ensure that the required capacity demand is met, the machine was designed with 2 heads. It can therefore chamfer 2 pipes at the same time to keep up with the operation.

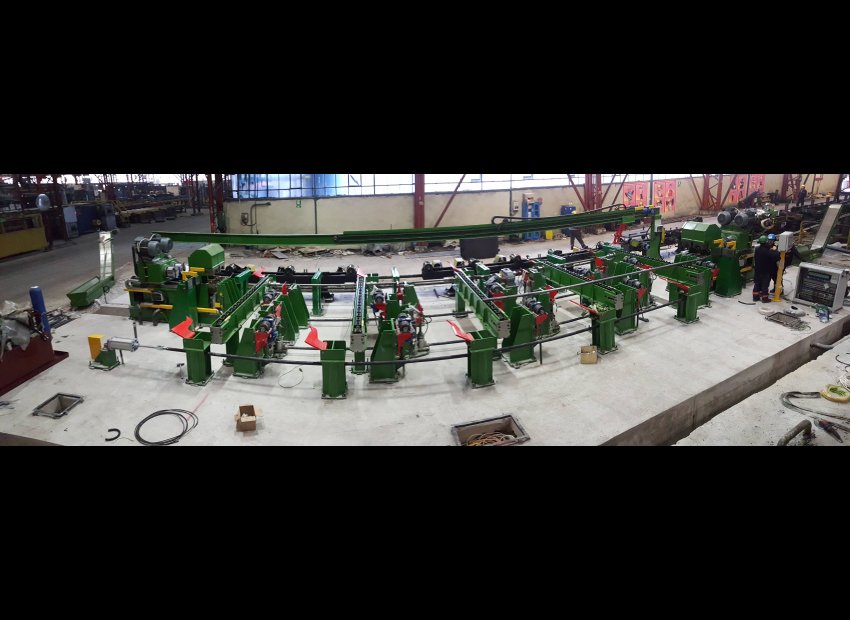

2.Chamfering Machine

Pipe Diameter: ½’’ – 3’’

Pipe length: 5m-12.8m

Capacity (max): 45 pcs/min for pipes shorter than 7.32 m

22.5 pcs/min on pipes longer than 7.32 m

This machine performs chamfering on all pipes that come from pipe machine (SRM machine). To ensure that the required capacity is met, the machine consists 2 chamfering units each with 2 heads. For pipes shorter than 7.32 meters, it works as if it's 2 separate chamfering machine. For pipes longer than 7.32 meters, it turns into a single chamfering machine.

When working with long pipes, the first head of the first chamfering machine and the second head of the second chamfering machine are online. The second head of the first chamfering machine and the first head of the second chamfering machine are moved under the surface with an elevator system. 2 chamfering machines can thus transform into a single machine. The transformation takes 2 minutes.

This machine (2 different chamfering machine defined above) was installed in only %10 larger the area of a single 12.8 meter chamfering machine,

Why ALBA Chamfering Machine?

-The design that covers the least amount of customers' available area.

-High capacity

-Fast and easy size change

-Reduced chamfering tip consumption.

-Quality

-Reduction in maintenance costs